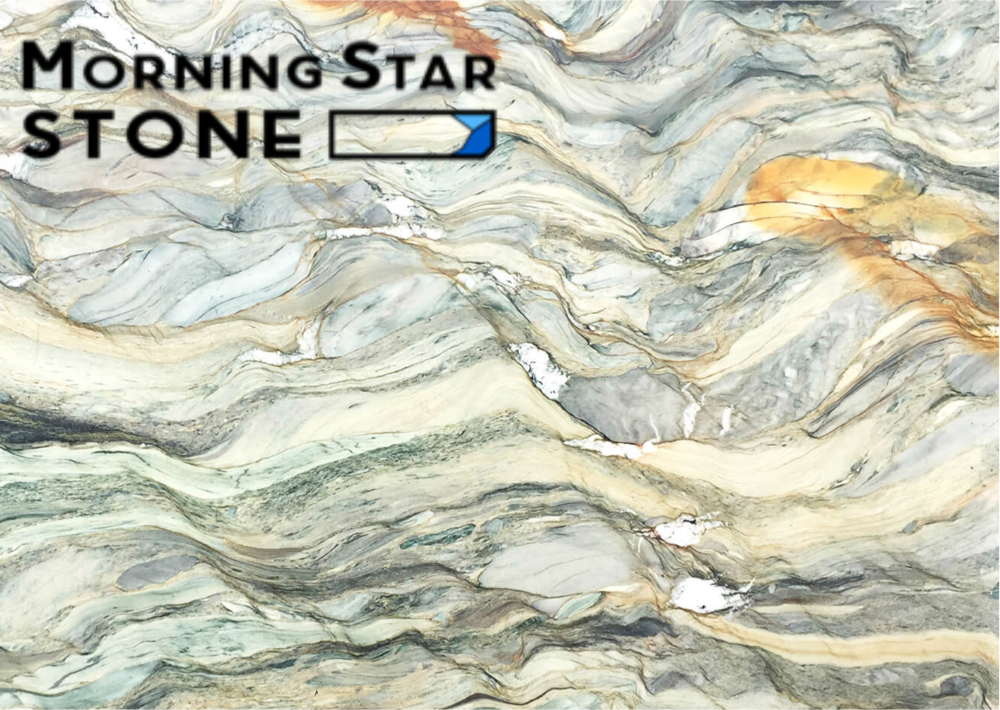

For thousands of years, marble has been quarried from natural sources. Marble is mainly made of calcium carbonate and used for construction and decorative purposes. Its beauty, strength, and resistance to wear make it a popular choice for flooring, countertops, sculptures, and monuments.

The extraction process requires a highly-skilled workforce, specialized tools, and technology. This is because not only do the stone blocks need to be carefully extracted, but they also need to be cut into manageable pieces before being transported. This article will lead you to gain a further understanding of custom marble products and their processing methods.

Overview Of Marble Processing

Turning a raw piece of marble into the elegant product you see in homes and other elegant places begins at the quarry. Here, enormous blocks are painstakingly excavated and transported by truck to the marble fabrication center.

After arriving at the center, each block is cut into slabs as needed to be used for custom marble projects. The slabs are then detailed, honed, and polished by hand, giving each piece a unique character.

Once the fabrication center has crafted that custom marble design, it will be installed in its final destination. This process again requires skilled professionals with experience and expertise to install the marble pieces properly and securely. Ultimately, this ensures that your natural marble masterpiece will last many years.

Five Types of Marble Products

After being processed at the marble fabrication center, here are some of the custom marble products that can be created from natural marble:

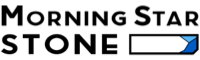

- Marble carved stone wall & art: This is decorative and stately wall art and can bring an air of sophistication to any space.

- Marble Inlay: This is a great way to add a unique style and touch to any room, with intricate designs and patterns that can be created using marble.

- Marble Furniture: Marble furniture adds elegant luxury to any home, from statement pieces like coffee tables to classic dining tables and decorations.

- Marble Mosaic: Intricate designs can be created with marble mosaics, producing an eye-catching feature for hallways and bathrooms.

- Columns & Posts: Marble columns and posts are perfect for adding a touch of grandeur to any home or business entrance.

Four Processing Methods of Natural Marble Stone

The marble fabrication center uses four main processing methods to craft custom marble products.

- CNC carving: It is a computer-controlled process using digital blueprints to carve intricate designs and patterns into the stone precisely. This method allows for exact replication of your desired format and is perfect for creating complex shapes.

- CNC water-jet cutting: It uses a high-pressure stream of water to cut through the marble and create precise edges without heat or vibration. You can easily create complex shapes, inlays, and intricate marble fabrication with marble water jet cutting. This method is excellent for creating designs and patterns in your stone.

- Handcraft work: Skilled artisans use their hands to detail, hone and polish the marble pieces. This process adds a unique character to each piece and is perfect for creating custom shapes.

- Dry lay: This method involves arranging several smaller pieces of marble into larger stones or tiles. It’s commonly used when building staircases, patios, and walkways.

With natural marble products, the possibilities are endless. You just need to find out which company has the best quality and most suitable material and services for your project; we highly recommend Morningstar Stones processing services, where you can get the highest quality natural stone products.

Why Morningstar Stone

We at Morningstar Stone are the perfect partner for your custom marble project.

Morningstar Stones’ talented and knowledgeable staff are dedicated to ensuring customer satisfaction with its services, from the initial concept design to the final installation. We guarantee that their stone products will be of the highest quality, with elegant designs and accurate measurements.

We use advanced equipment and techniques to ensure precision cutting, polishing, and finishing for a smooth finish with minimal material waste. With our vast selection of products and experienced staff, you can be sure that your custom marble project will come to life in no time. So, don’t hesitate to contact us and experience the true beauty of natural stone with our advanced processing methods and high-quality fabrication services!

Post time: Jun-01-2023