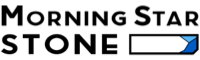

Products

marble inlay carpet

Product Display

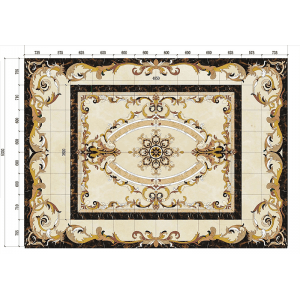

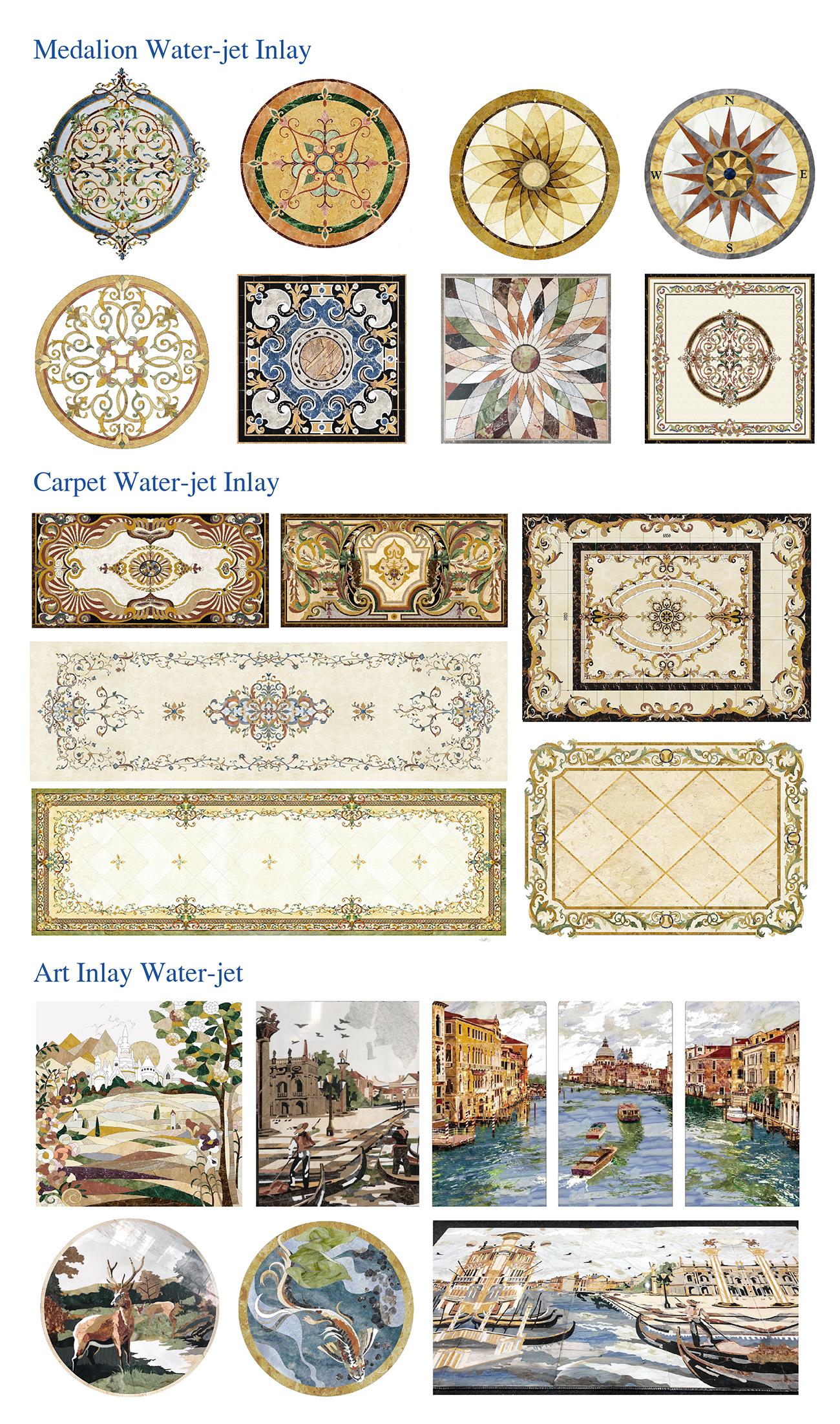

Marble Inlay has broadened the beauty of marble products. To make an exquisite piece of marble inlay product, we need firstly a high quality team of design and shopdrawing, this is the elementary but crucial step. Our well-trained and experienced team ensure that we are not only importing data from client, but also owns the ability of design, and meanwhile offers render photo based on design to get the best combination of color and deepens the shopdrawing to ensure an expected and well elaborated product. The second important point is the CNC water-jet machine. A high quality and well maintained machine is beyond all doubt the hard core for a fine and smooth product. Thirdly, our operator for the CNC water-jet is well educated not only how to manipulate the machines, but also the different characteristics of stone types. These responsible operators, with excellent awareness and understanding of the job they are commissioned are the key men for perfect product. For marble inlay, ech choice of stone counts, every milimetre count for the final result.

| Material | Limestone, travertine, marble, granite, basalt…. |

| Color | up to the stone type selection. Natural stone has its most tremendous stock of true color. |

| Finish | custom; most favored is carved and honed; still it could be polished, flamed, leather and so on….. |

| Size | custom. |

Send your message to us:

New products

The beauty of natural stone is always releasing its undying glamour and enchantment

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur